Rumored Buzz on Copper Foil

Wiki Article

The Best Guide To Copper Foil

Table of ContentsLittle Known Facts About Copper Foil.Not known Details About Copper Foil Indicators on Copper Foil You Should KnowThe Definitive Guide for Copper FoilThe Facts About Copper Foil RevealedWhat Does Copper Foil Do?What Does Copper Foil Do?Fascination About Copper FoilEverything about Copper Foil

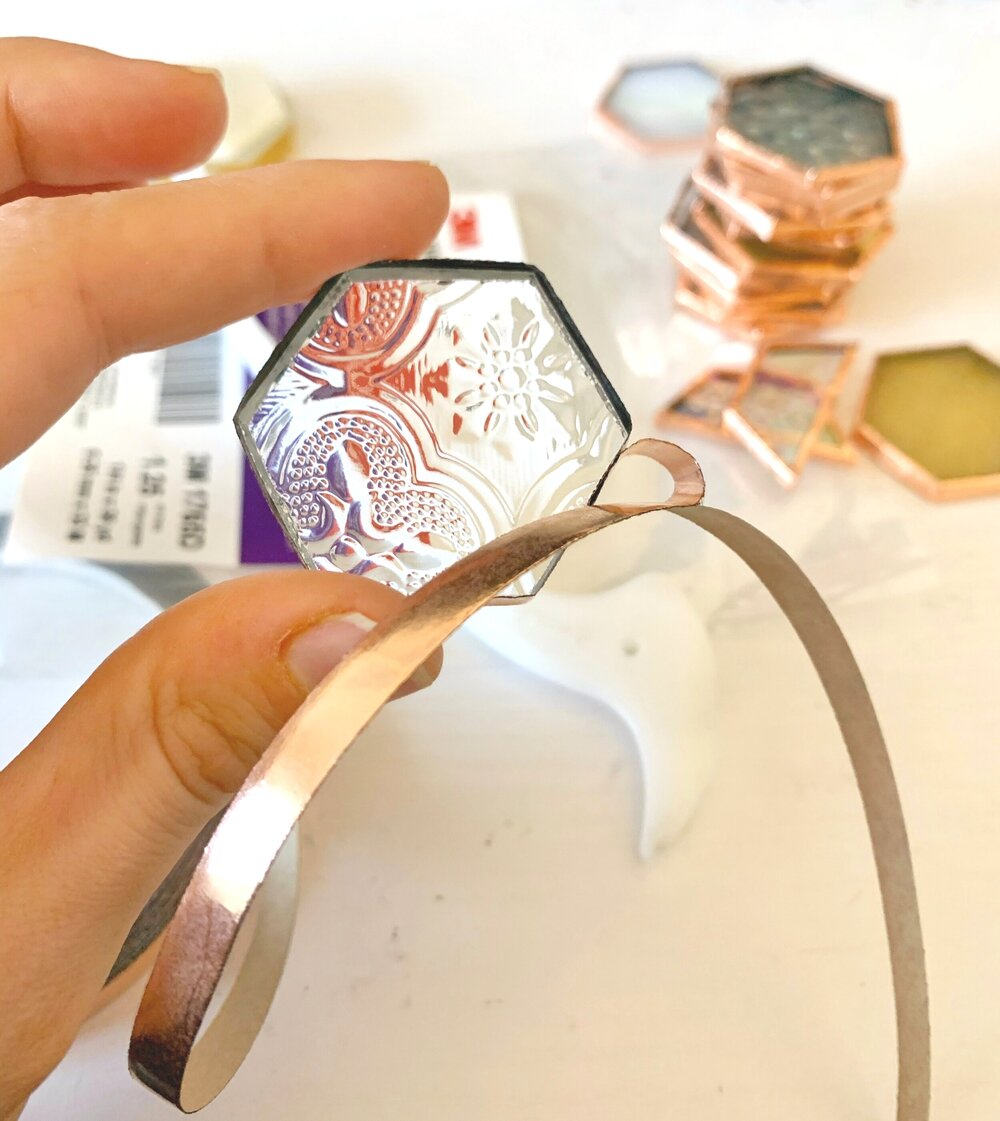

When you copper foil stained glass whole lots of questions come up that you weren't educated just how to deal with. Scroll down to locate a whole listing of answers to aid improve your stained glass copper hindering.If you aim for the copper aluminum foil you'll be place on. 3/16" 1/4" foil functions well for most conventional copper foil discolored glass pieces.

The smart Trick of Copper Foil That Nobody is Discussing

More About Copper Foil

The rolls fit perfectly and also when the lid is safeguarded in place, it aids preserve the aluminum foil. Beginning hindering away from the boundary of a piece When you copper foil stained glass it's finest to begin foiling far from the outside side as this makes for stronger bond. This is due to the fact that the foil isn't signed up with outside side where is is more probable ahead loose.

Do you recognize how to copper foil tarnished glass that is greatly textured? If you have actually attempted this you'll recognize that the foil breaks as you attempt to go from high to low. Even with superficial distinctive glass (surges) the aluminum foil often breaks as it goes across the surges rather than well contouring to it.

Copper Foil Can Be Fun For Everyone

Utilize a cork for kinking textured glass as it is softer as well as provides pressure while minimizing tearing. It cleans the foil also!Much better still, you can use a to eliminate the heavy structure on the glass before hindering. This truly aids with aluminum foil attachment. Before you get a rippled little bit see to it it will fit your grinder. Usage lined paper to assist centre the copper foil When you copper aluminum foil tarnished glass by hand it can be difficult have a peek at this site to centre the foil.

Copper Foil Things To Know Before You Get This

Usage lined paper as a guide! This is an interesting inquiry and one I obtain asked A LOT. My response could save you hrs of time grinding and also cleaning up. When you copper aluminum foil discolored glass you do not need to have a rough surface for the foil to stay with.Your glossy cut edges are great without grinding. Simply take care of your fingers. You can simply deaden the sharp edges off with a damp scythe rock to avoid cutting on your own and also to avoid sharp edges reducing the aluminum foil. Ground edges require to be completely cleansed before foiling. Sometimes when you copper foil tarnished glass the foil comes away from the side.

The Of Copper Foil

If you solder as well slowly or go over the solder consistently the foil adhesive thaws and also comes to be unstuck. It's worth keeping in mind that the adhesive exists to hold the foil in location till it's soldered. It does not serve to maintain it on when it's been warmed. Attempt raising the size of the outside aluminum foil a tiny little bit as well.

If you tin the sides instead than developing a handmade edge. "Tinning" indicates covering them with a slim finish of solder. "Beading" is a spherical side of solder that 'clings' to the side of the discolored glass and also is a lot stronger.

Electrical wiring demand is just one of one of the most crucial vehicle drivers for electronic bundle choice. The Semiconductor Sector Association (SIA) (Sematech) publishes a record regularly to suggest the sector of the present as well as future wiring need for a series of item kinds. Table site 1 shows components of the table that was released in 1999 (copper foil).

The Basic Principles Of Copper Foil

Reduced I/O remain in hand held items that endanger on efficiency to attain their smaller sized size. These I/O values are leading edge internet applications with the largest variety of I/Os. Typical applications have much lower need yet over time will reach the leading edge needs, which are 510 years in advance of the normal item.This only happens in limited layouts. The various other piece of the I/O equation is the dimension of the chip. This is generally a function of how many circuits are being made use of by the application. In Table 2, SIA (Sematech 1999) has actually defined chip dimension as a feature of the kind of application. copper foil.

The 5-Minute Rule for Copper Foil

In this technique, a gold or aluminum cable is bonded to a pad on the chip and after that looped to a pad on the chip provider, which is the base for the component. A normal chip to substratum connection making use of wire bond is kept in mind in Fig. 1. With distinct wires, their placement can not be also close or the wires will certainly touch each various other.Report this wiki page